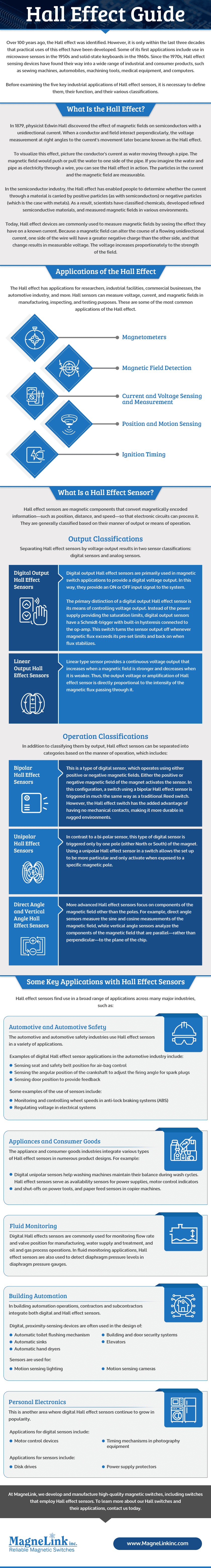

Hall Effect Guide

Over 100 years ago, the Hall effect was identified. However, it is only within the last three decades that practical uses of this effect have been developed. Some of its first applications include use in microwave sensors in the 1950s and solid-state keyboards in the 1960s. Since the 1970s, Hall effect sensing devices have found their way into a wide range of industrial and consumer products, such as sewing machines, automobiles, machining tools, medical equipment, and computers.

Before examining the five key industrial applications of Hall effect sensors, it is necessary to define them, their function, and their various classifications.

What Is the Hall Effect?

In 1879, physicist Edwin Hall discovered the effect of magnetic fields on semiconductors with a unidirectional current. When a conductor and field interact perpendicularly, the voltage measurement at right angles to the current’s movement later became known as the Hall effect.

To visualize this effect, picture the conductor’s current as water moving through a pipe. The magnetic field would push or pull the water to one side of the pipe. If you imagine the water and pipe as electricity through a wire, you can see the Hall effect in action. The particles in the current and the magnetic field are measurable.

In the semiconductor industry, the Hall effect has enabled people to determine whether the current through a material is carried by positive particles (as with semiconductors) or negative particles (which is the case with metals). As a result, scientists have classified chemicals, developed refined semiconductive materials, and measured magnetic fields in various environments.

Today, Hall effect devices are commonly used to measure magnetic fields by seeing the effect they have on a known current. Because a magnetic field can alter the course of a flowing unidirectional current, one side of the wire will have a greater negative charge than the other side, and that change results in measurable voltage. The voltage increases proportionately to the strength of the field.

Applications of the Hall Effect

The Hall effect has applications for researchers, industrial facilities, commercial businesses, the automotive industry, and more. Hall sensors can measure voltage, current, and magnetic fields in manufacturing, inspecting, and testing purposes. These are some of the most common applications of the Hall effect.

Magnetometers

Magnetometers, or Hall probes, measure the strength of magnetic fields, often for permanent magnets in engineering design evaluations. They can also be used to detect magnetic flux leakage in pipes and storage tanks.

Magnetic Field Detection

Magnetic field sensors and detection equipment can pick up the presence of magnetic fields and determine their magnitude. Once the fields are detected, a trigger can provide signals and data or switch power to a circuit.

Current and Voltage Sensing and Measurement

Sensors use the Hall effect to detect or measure direct currents. A Hall device can detect the presence of a magnetic field. In some cases, a Hall device can measure the voltage and determine the current, displaying it as a readable signal.

Position and Motion Sensing

In the case of magnetic field detection, this function is used widely in industrial and commercial equipment and machinery. A Hall effect sensor has the advantage of no mechanically moving components in detecting the presence of a magnetic field. They are used commonly as limit switches.

Complex machinery and vehicles also benefit from the Hall effect. When they detect fluctuations in voltage, these sensors transmit signals that can be implemented in tachometers, anti-lock braking systems in vehicles, and material handling assemblies.

Ignition Timing

The Hall effect’s capabilities to sense or control motion are crucial to proper ignition timing in internal combustion engines. Ignition timing is the precise release of a spark into a combustion chamber based on the position of the piston and the corresponding crankshaft angle.

What Is a Hall Effect Sensor?

Hall effect sensors are magnetic components that convert magnetically encoded information—such as position, distance, and speed—so that electronic circuits can process it. They are generally classified based on their manner of output or means of operation.

Output Classifications

Separating Hall effect sensors by voltage output results in two sensor classifications: digital sensors and analog sensors.

Digital Output Hall Effect Sensors

Digital output Hall effect sensors are primarily used in magnetic switch applications to provide a digital voltage output. In this way, they provide an ON or OFF input signal to the system.

The primary distinction of a digital output Hall effect sensor is its means of controlling voltage output. Instead of the power supply providing the saturation limits, digital output sensors have a Schmidt-trigger with built-in hysteresis connected to the op-amp. This switch turns the sensor output off whenever magnetic flux exceeds its pre-set limits and back on when flux stabilizes.

Analog (or Linear) Output Hall Effect Sensors

An analog type sensor provides a continuous voltage output that increases when a magnetic field is stronger and decreases when it is weaker. Thus, the output voltage or amplification of an analog Hall effect sensor is directly proportional to the intensity of the magnetic flux passing through it.

Operation Classifications

In addition to classifying them by output, Hall effect sensors can be separated into categories based on the manner of operation, which includes:

Bipolar Hall Effect Sensors

This is a type of digital sensor, which operates using either positive or negative magnetic fields. Either the positive or negative magnetic field of the magnet activates the sensor. In this configuration, a switch using a bipolar Hall effect sensor is triggered in much the same way as a traditional Reed switch. However, the Hall effect switch has the added advantage of having no mechanical contacts, making it more durable in rugged environments.

Unipolar Hall Effect Sensors

In contrast to a bi-polar sensor, this type of digital sensor is triggered only by one pole (either North or South) of the magnet. Using a unipolar Hall effect sensor in a switch allows the set up to be more particular and only activate when exposed to a specific magnetic pole.

Direct Angle and Vertical Angle Hall Effect Sensors

More advanced Hall effect sensors focus on components of the magnetic field other than the poles. For example, direct angle sensors measure the sine and cosine measurements of the magnetic field, while vertical angle sensors analyze the components of the magnetic field that are parallel—rather than perpendicular—to the plane of the chip.

Five Key Applications of Hall Effect Sensors

Hall effect sensors find use in a broad range of applications across five major industries, which are:

Automotive and Automotive Safety

The automotive and automotive safety industries use both digital and analog Hall effect sensors in a variety of applications.

Examples of digital Hall effect sensor applications in the automotive industry include:

- Sensing seat and safety belt position for air-bag control

- Sensing the angular position of the crankshaft to adjust the firing angle for spark plugs

Some examples of the use of analog type sensors include:

- Monitoring and controlling wheel speeds in anti-lock braking systems (ABS)

- Regulating voltage in electrical systems

Appliances and Consumer Goods

The appliance and consumer goods industries integrate various types of Hall effect sensors in numerous product designs. For example:

- Digital unipolar sensors help washing machines maintain their balance during wash cycles.

- Analog sensors serve as availability sensors for power supplies, motor control indicators and shut-offs on power tools, and paper feed sensors in copier machines.

Fluid Monitoring

Digital Hall effects sensors are commonly used for monitoring flow rate and valve position for manufacturing, water supply and treatment, and oil and gas process operations. In fluid monitoring applications, analog Hall effect sensors are also used to detect diaphragm pressure levels in diaphragm pressure gauges.

Building Automation

In building automation operations, contractors and subcontractors integrate both digital and analog Hall effect sensors.

Digital, proximity-sensing devices are often used in the design of:

- Automatic toilet flushing mechanism

- Automatic sinks

- Automatic hand dryers

- Building and door security systems

- Elevators

Analog sensors are used for:

- Motion sensing lighting

- Motion sensing cameras

Personal Electronics

This is another area where both analog and digital Hall effect sensors continue to grow in popularity.

Applications for digital sensors include:

- Motor control devices

- Timing mechanisms in photography equipment

Applications for analog sensors include:

- Disk drives

- Power supply protectors

Contact MagneLink Today

As outlined above, Hall effect sensors—both analog and digital—find application in a broad range of devices, equipment, and systems across a variety of industries.

At MagneLink, we develop and manufacture high-quality magnetic switches, including switches that employ Hall effect sensors. To learn more about our Hall switches and their applications, contact us today.