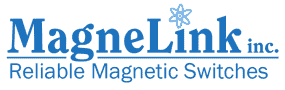

Industrial Magnetic Switch Applications

Magnetic switches offer a reliable and durable solution for detecting and controlling the position of mechanical components, making them essential in various industrial applications. These switches use magnetic fields to create a contact-free, wear-resistant switching mechanism that can withstand harsh operating conditions.

This blog will explore the different types of industrial magnetic switches, their industrial applications, and their benefits to various sectors.

Types of Industrial Magnetic Switches

Industrial magnetic switches are specifically designed to improve efficiency, safety, and performance across a wide range of applications. Here are their common types:

1. Proximity Switches

Designed to identify an object’s presence or absence without physical contact, proximity switches utilize magnetic fields to detect a target’s closeness. The switch generates a signal once the target is within a specified range. Thus, they are employed for object detection and position sensing in machine automation, robotics, and material handling applications.

2. Limit Switches

The primary function of limit switches is to detect the end-of-travel or limit positions of mechanical components such as linear actuators, slides, and doors. These switches comprise a switch body and a contact actuated by a magnetic field, opening or closing once a specific magnetic field threshold is met. Widely utilized in conveyor systems, assembly lines, and machine automation, limit switches play a critical role in both end-of-travel detection and safety interlocking.

3. Safety Switches

Safety switches are often used to ensure the safe operation of industrial equipment by detecting hazardous conditions and initiating protective measures. They often incorporate magnetic technology for contactless and wear-resistant operation, providing reliable performance even in harsh environments. They are used in robotics, material handling, and machine automation to prevent accidents and protect workers.

Common Functions of an Industrial Magnetic Switch

Magnetic switches are widely utilized across diverse industrial applications, such as:

- Position sensing: One of the primary functions of magnetic switches is to accurately detect the position of mechanical components. This ensures precise control and operation, optimizing processes and enhancing overall performance.

- End-of-travel detection: By identifying a component’s end-of-travel position, magnetic switches serve as a tool in preventing damage, maintaining functionality, and enhancing the safety of equipment and operators.

- Object detection: Sensing the presence or absence of objects is another critical function of an industrial magnetic switch. This capability enables efficient material handling and automation, streamlining workflows and reducing the likelihood of errors or accidents.

- Safety interlocking: Magnetic switches play a crucial role in upholding safety standards within industrial environments by identifying dangerous situations and triggering precautionary actions. Their functions encompass overseeing entry points, confirming proper machine positioning before the operation, and verifying the presence of safety barriers.

- Speed and direction sensing: In some applications, industrial magnetic switches can also measure the speed and direction of moving components. This information can be vital for process control, diagnostics, and maintenance.

Industrial Magnetic Switch Applications in Various Fields

Magnetic switches offer many benefits in various industries and serve many practical functions across diverse applications. These include the following:

- Machine automation:Magnetic switches are essential tools for monitoring and regulating the movement of mechanical components.

- Conveyor systems: An industrial magnetic switch detects product positions, manages material flow, and maintains proper alignment.

- Robotics: These components are crucial for precise positioning and controlling movement in robotics.

- Material handling: In material handling applications, magnetic switches are used to identify the presence of objects, monitor load conditions, and guarantee the safe operation of equipment.

- Assembly lines: Magnetic switches are key in assembly lines, enabling precise control over component positioning.

Experience the Power of MagneLink’s Magnetic Switch Solutions

Unlock your industrial applications’ potential with MagneLink’s diverse, high-quality magnetic switches. We are a trusted partner with years of experience and a commitment to innovation. Thus, you can rely on us for durable and efficient magnetic switch solutions for your business.

Contact us to discuss your needs, receive a personalized quote, or obtain more information about our products and services!