Rail and Trucking Magnetic Switch Applications

Leave a CommentMagnetic switches are an innovative solution that has revolutionized the transportation industry. Also known as magnetic contact switches, they are electrical devices that use sensors and magnets to control the flow of electricity. These switches detect changes in magnetic fields, enabling precise detection and control in transportation systems.

This blog post delves into the diverse benefits and applications of a transportation magnetic switch in rail and trucking operations.

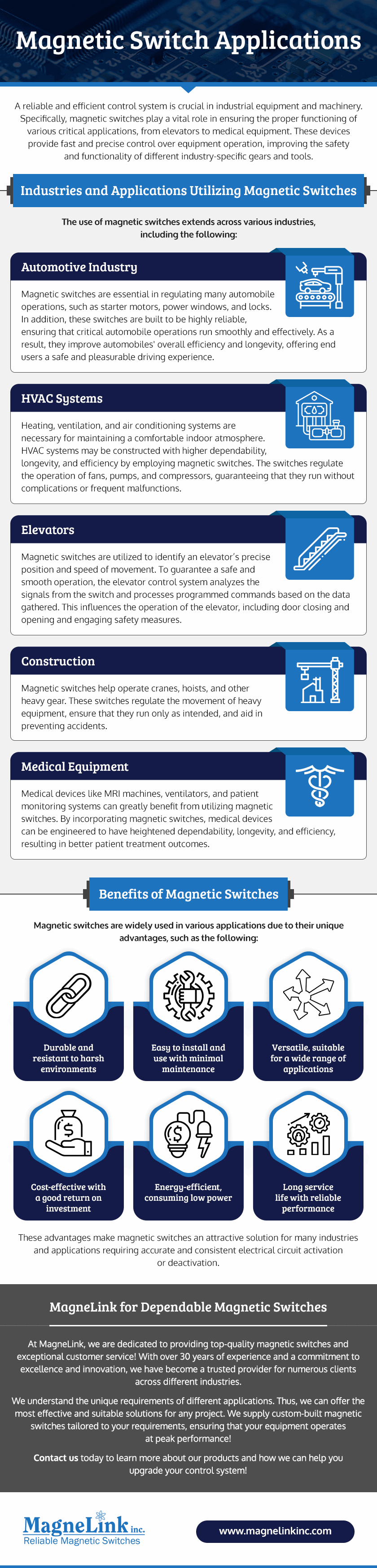

Advantages of a Magnetic Switch in the Transportation Industry

The adoption of magnetic switches in railways and trucking businesses offers several benefits over traditional methods:

- Enhances precision and accuracy: With precise detection of magnetic fields, magnetic switches ensure more accurate tracking and monitoring of vehicles and trains than traditional methods.

- Uses non-contact sensing: Unlike traditional methods that require physical contact with the object being detected, magnetic switches operate on a non-contact basis. This reduces wear and tear, minimizes maintenance requirements, and prolongs the lifespan of the detection system.

- Reduces false alarms: These switches are highly specific in detecting magnetic fields, leading to fewer false alarms compared to some traditional methods. This prevents unnecessary traffic interruptions.

- Saves cost: Utilizing a magnetic switch often proves cost-effective in the long run due to its durability, low maintenance requirements, and reduced false alarms.

- Integrates with automation: These switches can be easily integrated into automated systems, allowing seamless control and monitoring. This enhances the overall efficiency of transportation networks, leading to improved traffic flow and reduced congestion.

- Ensures safety: The precision of magnetic switches enhances safety in transportation operations whether it’s avoiding collisions on railway tracks or ensuring accurate vehicle detection at intersections.

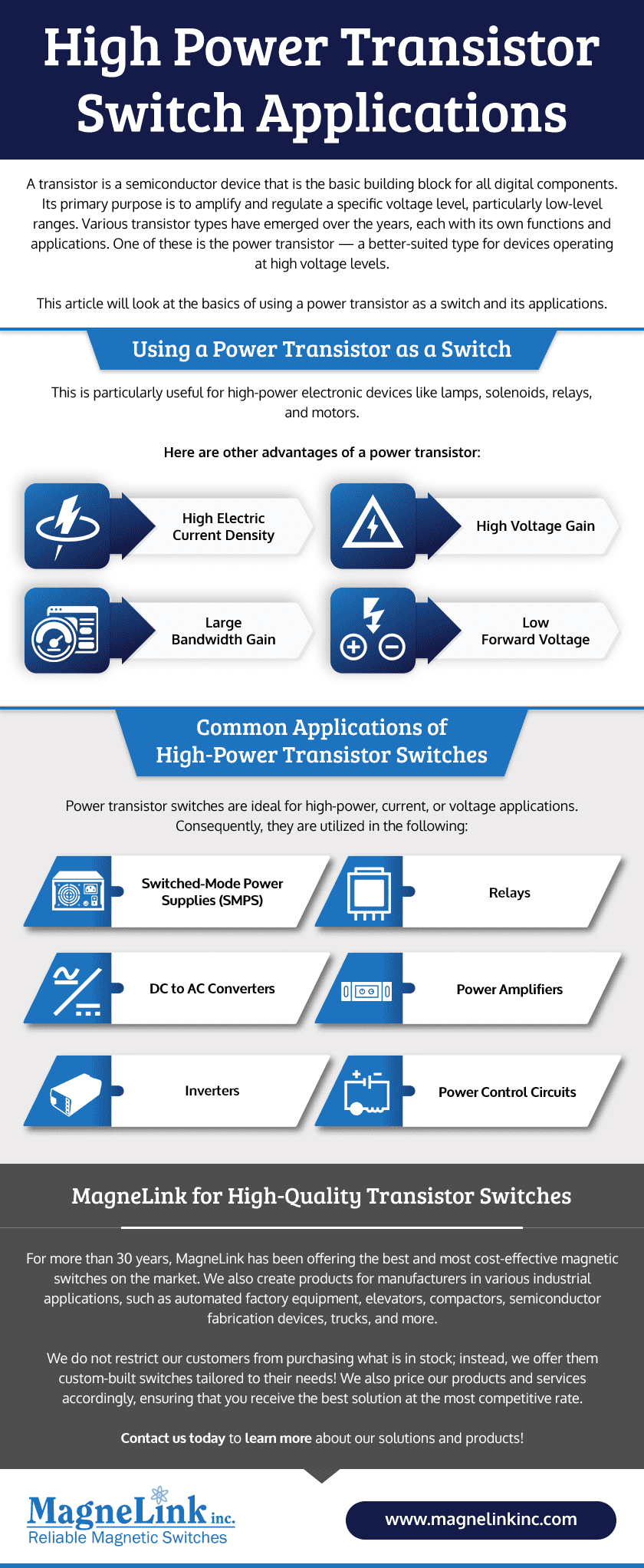

Key Applications in Rail and Trucking Operations

Magnetic switches are invaluable in the transportation industry, providing accurate and reliable data for monitoring and controlling trains, trucks, and other vehicles. Here are some of its uses:

1. Track Occupancy Detection

By placing magnetic switches strategically along the tracks, rail operators can determine the presence of trains on specific sections. This real-time data is crucial for efficient scheduling, avoiding collisions, and ensuring safe train movements.

2. Train Detection and Control

Installing magnetic switches at specific points on the tracks enables accurate train detection and control. Rail operators can monitor the position and speed of trains, which are essential for optimizing signaling systems, regulating train movements, and preventing accidents.

3. Level Crossing Safety

Magnetic switches are often integrated into level-crossing systems to enhance safety. When a train approaches, this device detects its presence and triggers warning signals, such as flashing lights and barriers, alerting motorists and pedestrians to stop.

4. Freight Tracking

In trucking and logistics, magnetic switches monitor freight containers during transit. Placed inside containers, these switches can detect movements, ensuring that cargo remains secure and intact throughout the journey. This enhances security, minimizes losses, and improves overall supply chain management.

5. Vehicle Detection in Trucking

At loading docks, weigh stations, and toll booths, a magnetic switch can detect the presence of vehicles and automate various processes. For instance, when installed at toll booths, they register the presence of vehicles. This allows for seamless electronic toll collection, reducing congestion and improving traffic flow.

6. Traffic Light Control

A transportation magnetic switch is often utilized to optimize traffic. By detecting the presence of vehicles waiting at intersections, they help in adjusting traffic signal timings dynamically. This adaptive approach reduces waiting times, improves traffic flow, and enhances overall road network efficiency.

7. Door Closure and Load Security

Magnetic switches provide reliable door closure detection, allowing transportation companies to confirm that the load is properly secured. This helps prevent accidents and losses due to unsecured cargo during transit. In addition, they are also widely used in refrigerated trailers to maintain controlled temperature. If a door is left open, the refrigeration system can be automatically adjusted, or an alert can be sent to the operator. This prevents unnecessary cooling and saves energy during transport.

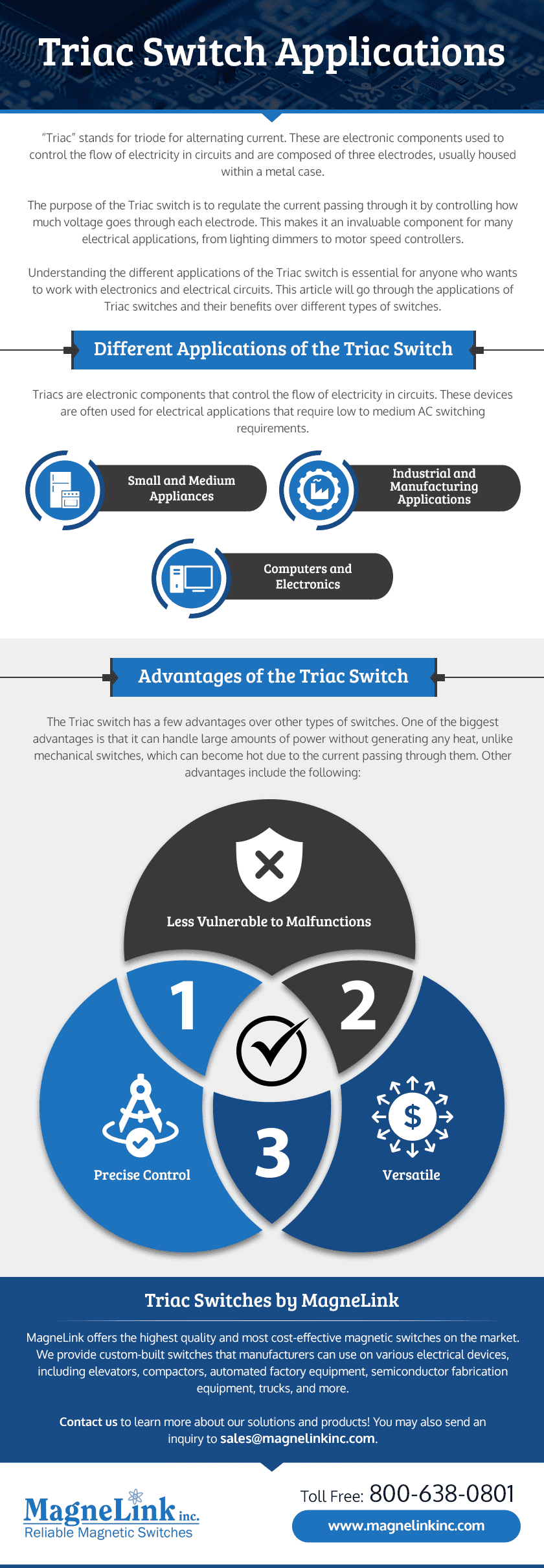

Upgrade to Top-Notch Magnetic Switches With MagneLink

MagneLink is at the forefront of innovative magnetic switch products. With over 30 years of crafting cutting-edge solutions, we have earned a reputation for delivering the highest quality and most cost-effective magnetic switches on the market. We take pride in our custom-built switches, meticulously designed to cater to various industries and applications, particularly in the transportation sector.

Discover the difference that premium and customized magnetic switches can make for your business! Contact us now to discuss your needs or request a quote for your tailored requirements.