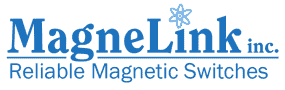

A Guide to Limit Switches

Leave a CommentMagneLink designs and manufactures magnetic switches for customers in a broad range of industries. We specialize

in the development of custom-designed magnetic switches engineered to meet particular application requirements. Our extensive selection of switches includes high-performance magnetic limit switches in various designs and configurations.

What Is a Traditional Limit Switch?

A limit switch is an automatic sensor assembly that requires direct physical contact to detect the position of an object or material. It is commonly used to monitor the presence/absence, proximity, and/or movement of items or materials within a system. Based on what it detects, an actuator opens or closes the electrical contacts, which automatically stops or starts the flow of electricity to connected equipment. This capability makes limit switches ideal for use in applications where strict limits must be observed.

What Is a Non-Contact Magnetic Limit Switch?

Non-contact magnetic switches are similar to traditional limit switches, but with the added advantage of operating without requiring physical contact between the switch and actuator. This added feature makes a non-contact magnetic switch a better performer in harsh or dirty environments, as well as making it more difficult to override. A non-contact magnetic limit switch also has a longer lifespan thereby reducing potential down-time for equipment repair.

How Does a Limit Switch Work?

The original purpose of limit switches was to monitor the movement of objects or materials within a system and stop their progression at a pre-set limit without the need for direct human intervention. They perform this function by having an actuator that breaks an electrical connection when an object or material comes into contact with it. This stops the operation of the equipment and, consequently, the movement of the load.

In other applications, a limit switch may make an electrical connection when an object or material comes into contact with it. This activates a connected device or system, enabling it to perform the necessary function for the situation.

Components of a Limit Switch

A standard limit switch consists of an actuator with an operating head, switch body, and electrical terminals.

- The operating head transmits the linear or rotary force from contact with the triggering object to the actuator.

- The actuator opens or closes the switch in response to the application or removal of force.

- The switch body contains the switch contact mechanism that opens or closes the connections between electrical terminals.

- The electrical terminals connect the switch to the electrical circuit it is controlling.

Industrial applications often require highly durable and reliable switches that can withstand heavy use without compromising accuracy. Limit switches can be customized to meet the needs of particular equipment and operations. By adjusting the size, mounting, stroke rate, electrical rating, and operational force of the switch, you can ensure dependable, safe equipment operation even in harsh industrial conditions.

Types of Limit Switches

There are many types of limit switches, each of which offers unique characteristics that make it suitable for different uses and environments. They can be divided into four categories based on the operating head design and actuation method:

- Non-contact magnetic limit switch: Non-contact magnetic limit switches are highly responsive switches that are controlled using a magnet actuator on a moving component of the equipment (i.e. door, gate, piston). The actuator triggers the switch when in close proximity to it. The switch can then electrically trigger alarms, shutoffs, etc. Non-contact magnetic limit switches offer a quick response time, making them an excellent choice for applications in door switches, elevators, light switches, lifts, conveyors, pressure switches, and temperature switches.

- Whisker limit switch: Whisker limit switches have a long flexible spring arm (i.e., whisker) that bends when an actuating force is applied and springs back to its normal position when it is removed. They are often used in conveyor and assembly line applications, where they can monitor the flow and placement of materials and sound an alarm if items are out of place.

- Roller limit switch: Roller limit switches use a roller on a stationary shaft to measure the flow of material or the number of items passing down a line or conveyor. They measure item quantity, volume, or flow based on the number of roller revolutions.

- Lever limit switch: Lever limit switches are highly responsive switches that are controlled using a lever mounted on a rotating shaft. The lever allows motion to continue to a pre-set limit. Once the lever rotates around the shaft to the limit point, the switch opens the circuit, triggering alarms or shutoffs. Lever limit switches provide a very quick response time, which makes them ideal for use in door-open indicators, elevators, lifts, conveyors, pressure switches, and temperature switches.

- Plunger limit switch: Plunger switches are equipped with a plunger that requires less physical force to activate than other limit switches. The plunger is connected to a spring and electrical contact such that it opens or closes the circuit when it is depressed. They are ideal for use in filling and conveyor applications where quick response time is a must.

Limit switches can also have a design that combines characteristics of two of the above four types.

Applications & Uses for Limit Switches

Limit switches are incorporated into a variety of flow control, conveyance, and sensing applications. They are durable, versatile, and accurate, with a range of designs, mounting systems, and sizes to meet even the most stringent specifications. Some of the most common applications for limit switches include:

- Conveyors: Limit switches are used to monitor and control the location, speed, and quantity of material and objects in conveyor applications.

- Assembly lines: Assembly lines use limit switches to monitor and control the location, position, quantity, and speed of components on the assembly line.

- Magnetic control circuits: Limit switches are used in electric motors to control start, stop, acceleration, and deceleration operations.

- Emergency systems: Limit switches are used to notify operators of equipment malfunctions, overloading, temperature fluctuations, pressure extremes, open enclosures, and other conditions that can affect the safety of your operation.

- Appliance lights: Limit switches are incorporated into ovens, refrigerators, microwaves, and other household devices that activate lights when you open the door.

- Automotive systems: Limit switches are used to turn on interior vehicle lights when the door is opened. They are also incorporated into automotive manufacturing and assembly equipment.

- Counting operations: Limit switches are used to count the number of products on conveyors for production, assembly, packaging, and other industrial and manufacturing operations.

- Fill stations: For operations that use buckets, baskets, boxes, and other containers, limit switches are used to automatically detect when a container is full for faster and more accurate filling operations.

Magnetic Switches From MagneLink Inc.

At MagneLink, we pride ourselves on providing superior quality limit switches to customers in virtually every industry. Whether you need a simple limit switch for refrigerator doors or complex safety shutoff limit switches for heavy industrial operations, our seasoned experts can help you find the perfect solution. Our limit switches are available in a wide selection of configurations, including Reed switches, Hall Effect switches, triac and transistor switches, coded switches, and interlock switches. To learn more about our product solutions, contact us today.

About Non-Contact Interlock Switches

Leave a CommentNon-contact interlock switches are essential in operations that require safe and secure protective doors. When equipped, these switches can power down a machine while the switch mechanism is activated, which usually occurs when opening the door, cover, or gate. The switches can operate using induction, magnets, or transponders.

At MagneLink Inc., we produce top-quality magnetic safety interlock switches for a variety of applications. Here we’ll provide an overview of the benefits of using non-contact interlock switches, the different types available, and their potential applications.

Benefits of Non-Contact Switches

Non-contact interlock switches offer these advantages:

- Excellent protection against tampering

- Extremely hygienic environments

- High safety levels

- Vibration minimization for machine doors

- Effective protection when used in wet, oily, or dusty conditions

Non-contact switches are a low-wear, low-maintenance option to prevent equipment from damaging itself or operators. They also provide safe position monitoring and prevent unauthorized access to secure areas.

Types of Non-Contact Interlock Switches

There are three main types of non-contact interlock switches, which work in different ways.

Magnetic Non-Contact Switches

These switches feature a sensing range of around 0.5 in., depending on variables within the application. This provides sufficient tolerance for doors that are misaligned and require a more effective solution than a conventional interlock switch. In addition, the non-contact nature of these switches minimizes wear over time, as the actuator never physically touches the switch.

Coded Magnetic Non-Contact Switches

Coded magnetically operated non-contact safety switches add another layer of security. With coded magnetic non-contact switches, a specific magnet must be used to activate the switch. Since the coded magnetic switch cannot be activated with a standard magnet, this configuration makes the switch even more defeat-resistant.

Uses for Non-Contact Interlock Switches

Non-contact interlock switches are crucial for a variety of applications. Facilities frequently use them in machine safety applications to securely interlock doors, gates, covers, and guards. Non-contact interlock switches are also important in locations with stringent hygiene requirements, including food processing and medical facilities.

Other uses for these switches could include:

- Position limit switches on factory equipment

- Vehicle door sensing switches

- Door / closet light switching for energy savings

- Mechanical safety interlock switches

Reliable Magnetic Non-Contact Switches from MagneLink

Non-contact interlock switches are the ideal solution for protecting workers in hazardous environments and creating a secure locking system in your facility. At MagneLink, we carry a range of magnetic non-contact interlock switches for nearly any application. To find out more about our solutions and products, contact us today.